Custom Wood Counter Tops

1275 BLOOMFIELD AVE. BLDG#10 FAIRFIELD, NJ

(973)299-6100

GOT BIG WOOD?

FROM SOFT TO HARD

HOURS:

Monday - Friday - 7:30am - 5:00pm

Saturday - 8:00am - 1:00pm

Sunday - Closed

COUNTER TOPS, KITCHEN ISLANDS, BAR TOPS

We custom fabricate Bathroom Vanities, Kitchen Counters/Islands, Table Tops, and Bar Tops. Choose from our large and unique selection of wood slabs and hardwood lumber. We will work closely with your general contractor to ensure precise measurements and dimensions for your ideal slab.

LEAD TIMES: Our lead times for custom tops can vary from 2-6 weeks depending upon work loads.

Generally reclaimed tops tend to have a longer lead time than new material.

Reclaimed Antique Oak

Call For Availability

Surfaced reclaimed oak barn beams that are resawn to required thickness and glued together to desired width.

Reclaimed Antique Heart Pine

2" Thick

With Oil Finish

Reclaimed Heart Pine from Structural Factory Beams that are resawn to required thickness and glued together to desired width.

New Butternut Boards

1 3/4" Thick

With Oil Finish

This process uses butternut board stock planed smooth and sanded with hand scraped edges and simulated board joints.

Black Walnut Slab

This process uses black walnut slabs either full width or glued up book matched to achieve wider widths.

New Random Mixed Boards- Maple & Walnut with Simulated Live Edge

1 3/4" Thick

With Oil Finish

This process uses board stock which is then glued together and a simulated live edge will be cut on outer edges.

New Book Matched Wood Slab with Center Boards to Width 1-3/4" Thick

With Oil Finish

This process uses two outer wood slabs and board stock of the same or different species to increase the width.

New Saw Kerf Pine Boards

1 3/4" Thick

With Oil Finish

This process uses pine board stock with saw kerf marks. This counter will have simulated nail holes and hand scraped edges. This will be sanded smooth but still retain the saw marks.

New Wormy Maple Boards

1 3/4" Thick

With Oil Finish

This process uses wormy maple board stock glued up planed smooth and sanded with simulated live edge. This is a lower cost way of making the wood slab look.

New Black Walnut Boards

1 3/4" Thick

With Oil Finish

This process uses black walnut board stock glued up planed smooth and sanded with simulated live edge. This is a lower cost way of making the wood slab look.

ADDITIONAL DECORATIVE OPTIONS

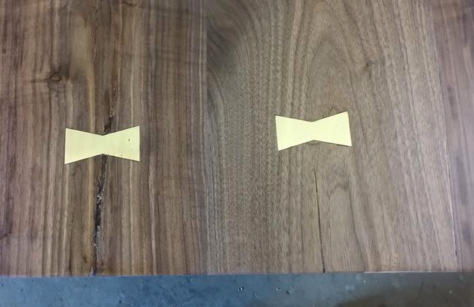

Wood Buttterflies

$75-$100/ea

These are used for stitching and securing endgrain checking in wood slabs. These can be made from any species of hardwood and can be used to add a decorative touch.

Brass Buttterflies

$75/ea

These are used for stitching and endgrain checking in wood slabs. Brass will add a more contemporary touch and a clear coat will be applied to prevent tarnishing.

Metal Flat Straps

2" Wide @ $42.60/LF

This strap is used as a decorative detail that is routered and set into the counter flush with surface to add a vintage and industrial look.

Wedging Mortise & Tenon $150

This mortise & tenon is used on the ends of a horizontal stretcher to hold the slab table legs together. This is a decorative and strong joint.

Corner Metal

$25 Per Corner

This metal detail is used as a decorative detail for the corners of our tables.

Steel Butterflies

$55/ea

These are used for stitching and securing end grain checking in wood slabs. The steel will add a more vintage or industrial look and a clear coat will be applied to prevent oxidation.

Counter Sunk Trough Bolts

This system is used for bolting heavy or larger timber table tops together when gluing is not used. Square head nuts will be counter sunk.

Surface Through Bolts

This system is used for bolting heavy or larger timber table tops together when gluing is not used. Square head nuts will not be counter sunk.

Metal Table Leg Bracket

This metal bracket will be used for joinery of timber vertical legs to horizontal foot. This is used decoratively and structurally.

Finger Corner Skirt

This system is used as a decorative detail to join the corners of skirt boards under the table top.

Metal Grommets System

This system is used as a decorative detail for edges of tables, counters and benches.

New Walnut Slabs on Outer Area and Walnut Boards to Widen the Width

1 3/4" Thick

With Oil Finish

This process uses two book matched or random walnut slabs for outer perimeters and kiln dried walnut boards to fill in the center to widen the width.

New Simulated "Authentic" Live Edge

This is an additional $10 per square foot added to any given species of wood.

THINGS TO KNOW:

Solid wood counters, unlike counters made from veneer surface and engineered substrate are more prone to bending with the directions of the grain and that is why they will require support of counter with overhangs of 8" or more depending on size. If counter wood grain overhangs in the opposite direction it can overhang 16" without adding any support.

Installation- Things to consider

Depending on which solid wood counter you are installing, whether it's a counter made from solid wood boards that are glued up side by side made from new or reclaimed lumber or wood slabs cut from a log or tree it is natural for a wood counter to expand and contract during weather and humidity changes. All wood counters should be secured with screws with slotted holes so expansion and contraction can facilitate with slots, unslotted screw holes may cause splitting of counter along glue joints or areas of weaker straight grain.

Considering that wood slabs are not dried to a moisture content of 7% such as glued up boards, wood slabs have a higher moisture content of about 12-15% which results in that wood slabs shrink and expand more which will refrain the screws to be installed in the outer portion of the slotted holes.

Adequate hold down support must be installed. Counter must not overhang in an area perpendicular to the grain (meaning at its width) more the 6” with either wood or metal brackets on its spine must have support no more the 48” apart and a maximum of 12” over hang on its lengths direction Wood counter will never warp or twist if properly secured. Boards & Beams will NOT be held liable for counter or table (twisting and or warping) by customer or contractor.

Counter or tabletop made by Boards & Beams should be installed and secured within a day or two of delivery to prevent warping , twisting or cupping of product can not be installed with that time frame. Product should not be stored in a damp area such as garage or basement or any out building should not be stored vertically against a wall or other building material against it. Product should not be stored near a HVAC vent with direct air blowing.

Warranties on Counters

Boards & Beams will NOT be held responsible for any warping, splitting, bending, checking or twisting due to improper installation or if the top moved during the acclimation process.

Bases where the tops are being installed should be adequately engineered.

Your counter will come with a 3 month workmanship warranty which includes glue joints, improperly sanded surfaces, and unsightly touch-up. Finished surface scratches are not covered days after counter has been delivered. Counters will only be covered under warranty on the day it was delivered. We advise every one of our customers to inspect their counter when being delivered. In the case of any scratches upon delivery, Boards & Beams, will refinish the counter at no cost.

Boards & Beams will not cover counter if altered by owner from its original size and shape. All warranties will be voided but Boards & Beams will make repairs at a fee to the customer.

Care of your Counter

Solid wood counters are no different than any other wood furniture in your home. A damp sponge with a little soap can be used to clean most spills or messes. No harsh chemicals, detergents, abrasive pads or steel wool should be used. Although your new counter might resemble a Butcher Block keep in mind that it is not a Butcher Block. Our counters are closer to fine furniture which should be cared for in the same way. Cutting boards and mats must be use on all of our counters as they are finished with high quality commercial grade lacquer or conversion varnish but are not 100% prone to scratches. Such care must be taken to prevent damage to your counter.

Butcher Block Counter Tops - Table Tops

Island Tops

Prices range from $27 to $54/SF

Multi-species - kiln dried - sanded & glued. Top thicknesses range from 1"-2" and widths up to 48". Lengths up to 16'.

Note: ** New updated services provided by Boards & Beams **

We are no longer offering ANY Custom tops/tables. Only our standard tops that we stock in house.